Laser machining stands as a cornerstone in numerous industries, facilitating precise drilling, cutting, and processing of materials at varying scales. To meet the escalating demands for ultra-high precision, researchers at Tohoku University have unveiled a pioneering method harnessing radially polarized laser beams to enhance processing resolution. Their breakthrough, detailed in the journal Optics Letters, promises to revolutionize laser material processing, opening new vistas for nano-scale applications across diverse sectors.

Unveiling the Potential of Vector Beams: Conventional laser processing techniques have long grappled with limitations in achieving sub-100 nanometer scales, necessitating innovative approaches to push the boundaries of precision. Enter radially polarized laser beams, characterized by a longitudinal electric field that yields a smaller focal spot compared to conventional beams. While promising for nano-processing, these beams encounter challenges related to field weakening within materials due to light refraction at air-material interfaces.

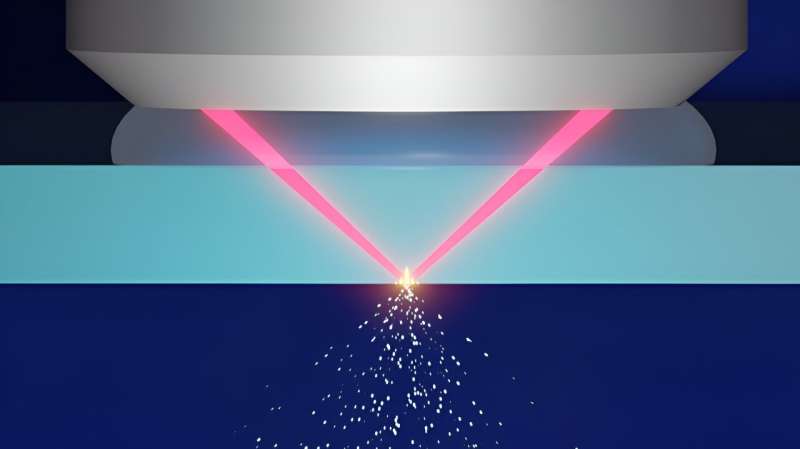

Overcoming Limitations with Immersion Optics: To address this hurdle, the researchers turned to oil immersion objective lenses, commonly employed in biological microscopes. Leveraging the nearly identical refractive indices of immersion oil and glass substrates, they mitigated light refraction, enabling the preservation of the longitudinal field within the material. This innovative approach circumvented the inherent limitations of conventional processing methods, laying the groundwork for enhanced precision at nano-scales.

Enhanced Field Confinement via Annular-Shaped Beams: Further exploration of radially polarized beams revealed a novel strategy for enhancing longitudinal field intensity. By employing annular-shaped beams, researchers leveraged total internal reflection at high converging angles on the back surface of the material, resulting in a significant amplification of the longitudinal electric field. This breakthrough culminated in the creation of a minute focal spot, setting the stage for unprecedented precision in laser material processing.

Realizing Sub-100 Nanometer Resolution: With the novel technique in hand, the researchers embarked on laser processing experiments using ultra-short pulse laser beams on glass substrates. Remarkably, a single shot of the converted pulse yielded a hole with a diameter of a mere 67 nanometers—approximately 1/16th of the laser beam’s wavelength. This remarkable achievement represents a paradigm shift in laser precision, offering a pathway to direct material processing at nano-scales previously unattainable.

Implications and Future Prospects: The implications of this breakthrough extend far beyond the realms of academia, with profound implications for industries reliant on high-precision manufacturing, such as semiconductor fabrication, biomedical engineering, and optical device production. By unlocking the potential of radially polarized beams, the research paves the way for transformative advancements in nano-processing, ushering in a new era of innovation and discovery. As researchers continue to refine and expand upon this groundbreaking technique, the horizon of possibilities for laser material processing is boundless, heralding a future defined by unparalleled precision and efficiency.

In the realm of laser science, the quest for ever-greater precision drives innovation and progress. The breakthrough achieved by Tohoku University researchers in harnessing radially polarized beams for nano-processing represents a seminal advancement with far-reaching implications. By surmounting longstanding barriers to sub-100 nanometer resolution, this pioneering technique heralds a new chapter in laser material processing, offering a glimpse into a future where precision knows no bounds. As we embark on this journey of discovery, the fusion of cutting-edge research and technological ingenuity promises to reshape industries, propel scientific inquiry, and unlock the full potential of laser precision in the 21st century and beyond.