In the realm of nanotechnology, the ability to fabricate intricate nanostructures with precision and efficiency is paramount for advancing various fields, including biomedicine, photonics, and information technology. Helical metal nanoparticles, with their unique chiral properties, hold immense potential for applications ranging from biodetection to data storage. However, traditional fabrication methods have been complex, expensive, and time-consuming, limiting their widespread adoption. In a groundbreaking study, researchers at the University of Michigan have unveiled a revolutionary approach to nanofabrication: light-powered 3D printing of helical nanostructures. This article explores the innovative technique developed by the University of Michigan researchers, its implications for diverse industries, and the potential for ushering in a new era of nanoscale manufacturing.

The Need for Simplified Nanofabrication: The demand for chiral surfaces capable of manipulating light at the nanoscale has surged in recent years, driven by advancements in biomedical and optical technologies. Chiral surfaces exhibit asymmetry in their molecular structure, enabling them to interact with light in unique ways. These surfaces play a crucial role in biosensing, drug discovery, and optical data processing. However, the complexity and cost associated with traditional fabrication methods have hindered their widespread adoption. The University of Michigan researchers recognized the need for a simpler, more scalable approach to nanofabrication—one that could democratize access to chiral surfaces and accelerate innovation in various industries.

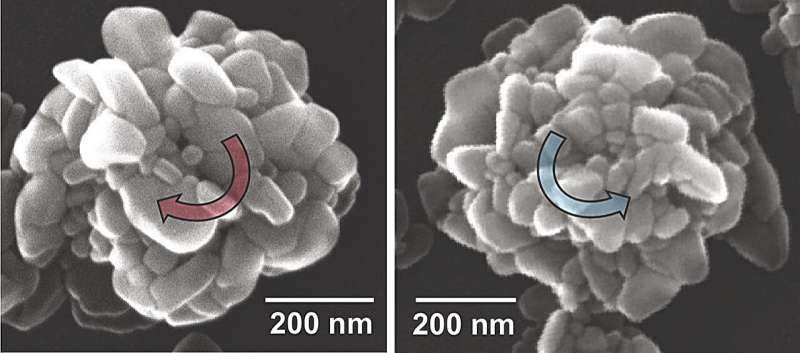

Light-Powered 3D Printing: The key innovation introduced by the University of Michigan researchers is the use of helical light beams to 3D print nanoscale helices with precise control over their handedness and pitch. Unlike conventional 3D printing technologies, which lack the resolution needed for nanoscale fabrication, this approach leverages the unique properties of helical light to achieve unprecedented precision. By aligning the helices’ axes with the direction of the light beam, the researchers can rapidly produce centimeter-scale chiral plasmonic surfaces with remarkable efficiency. This breakthrough holds immense promise for streamlining the production of complex nanostructures and unlocking new possibilities in nanoscience and nanotechnology.

Advantages of Light-Driven Printing: The use of light-driven printing offers several advantages over traditional nanolithography techniques. First and foremost, it eliminates the need for highly specialized hardware and costly processing steps, making nanofabrication more accessible and cost-effective. Additionally, the simplicity of the process allows for rapid prototyping and iteration, enabling researchers to explore novel designs and applications with ease. Moreover, light-driven printing offers superior spatial resolution and polarization rotation, paving the way for the creation of intricate nanoscale architectures previously deemed unattainable. These advancements have the potential to revolutionize a wide range of industries, from healthcare to telecommunications, by enabling the development of next-generation optical chips and sensors.

Implications for Biomedicine and Photonics: In the field of biomedicine, chiral plasmonic surfaces hold promise for revolutionizing biodetection and drug discovery. These surfaces can selectively bind to specific biomolecules, enabling highly sensitive and accurate diagnostic tests for various diseases. Moreover, they can facilitate the development of targeted therapeutics by detecting drug-resistant bacteria and mutated proteins. In photonics, chiral nanostructures offer unprecedented control over the manipulation of light, opening new avenues for enhancing data storage capacities and processing speeds. By harnessing the power of light-driven printing, researchers can accelerate the pace of innovation in these critical areas and address pressing challenges in healthcare and technology.

Future Directions and Outlook: As the field of nanofabrication continues to evolve, the University of Michigan researchers are poised to lead the way in advancing light-powered 3D printing technologies. Future research endeavors will focus on refining the printing process, expanding the range of printable materials, and exploring novel applications in diverse industries. Collaborations with industry partners will facilitate the transition of this technology from the laboratory to commercial-scale production, unlocking its full potential to transform manufacturing processes worldwide. With its ability to simplify nanofabrication and unleash the power of chiral nanostructures, light-driven printing represents a paradigm shift in the field of nanotechnology, heralding a new era of innovation and discovery.

The development of light-powered 3D printing of helical nanostructures marks a significant milestone in the field of nanofabrication. By harnessing the unique properties of helical light beams, researchers have unlocked a powerful tool for rapidly producing complex nanostructures with unparalleled precision and efficiency. This breakthrough has far-reaching implications for diverse industries, including biomedicine, photonics, and information technology, where chiral surfaces play a crucial role in advancing innovation. As researchers continue to push the boundaries of nanoscience and nanotechnology, light-driven printing promises to revolutionize manufacturing processes and pave the way for a future defined by unprecedented levels of precision and control at the nanoscale.