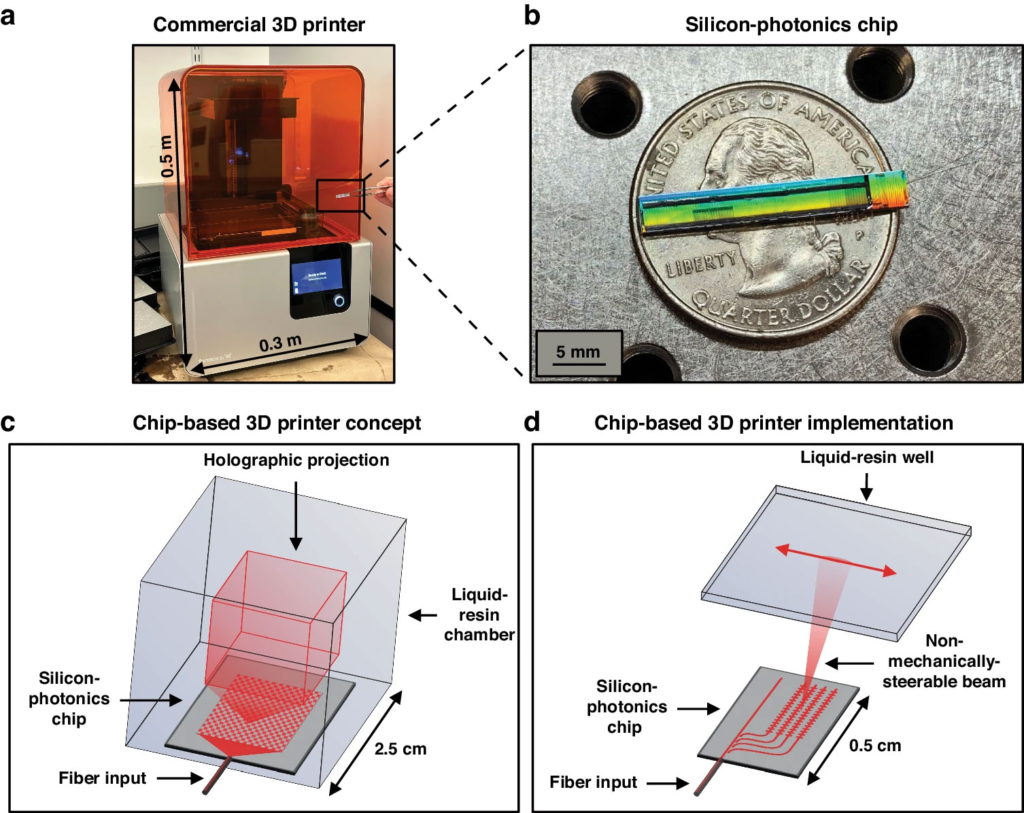

The advent of 3D printing has revolutionized manufacturing, particularly for low-volume production. However, traditional 3D printers are often bulky and cumbersome, requiring a stable platform for optimal functionality. A recent breakthrough by researchers from MIT and the University of Texas at Austin promises to change this narrative. They have developed a prototype 3D printer that is smaller than a coin, offering unparalleled portability and convenience.

This innovative device utilizes a photonic chip that directs a focused beam into a resin well. When exposed to a specific wavelength of light emitted by the chip, the resin rapidly cures, enabling precise fabrication of desired shapes. Unlike conventional 3D printers, which rely on mechanical components to adjust the beam’s focal point, this palm-sized printer eschews moving parts. Instead, it employs tiny optical antennas to manipulate the beam, enhancing efficiency and compactness.

If successfully commercialized, this chip-based 3D printer could revolutionize instant manufacturing. Its portability and speed would empower a wide range of users, including engineers, doctors, and first responders, to create solutions on-the-fly without the need for cumbersome equipment.

For instance, in the medical field, an orthopedic surgeon could utilize a 3D scanner to capture a patient’s broken bones during surgery. Subsequently, a biomedical engineer could design a custom bone implant to aid in fracture healing, which could then be printed using the portable 3D printer and biomedical resin.

Moreover, the compact nature of this 3D printer makes it ideal for space exploration missions such as NASA’s Artemis program. Its lightweight and portability would facilitate on-demand fabrication of tools and parts required by the crew during missions.

These applications represent just a glimpse of the transformative potential of this 3D printing concept. MIT Professor Jelena Notaros envisions a paradigm shift in the field of 3D printing, stating, “This system is completely rethinking what a 3D printer is. It is no longer a big box sitting on a bench in a lab creating objects, but something that is handheld and portable. It is exciting to think about the new applications that could come out of this and how the field of 3D printing could change.”

The evolution of 3D printing technology has been remarkable since its inception. From metal 3D printers on the International Space Station facilitating moon and Mars missions to affordable options like the $77 3D printers available on AliExpress, the accessibility and versatility of 3D printing have expanded exponentially. Furthermore, the development of affordable large-scale 3D printers capable of printing objects the size of a small child underscores the scalability of this technology.

In conclusion, the creation of a miniature 3D printer by MIT and the University of Texas at Austin represents a significant milestone in the field of additive manufacturing. Should this project progress to retail availability, it could democratize 3D printing, empowering individuals from various disciplines to unleash their creativity and innovation with a device that fits in the palm of their hand.

If you like the article please follow on THE UBJ.